The country's manufacturing sector is crying for cheap funds for re-tooling to improve performance and production of quality goods, with little success.

A number of companies in Zimbabwe, and Bulawayo in particular, are in dire need of retooling, as they are using obsolete machinery, designed in the early 1940s.

According to the Confederation of Zimbabwe Industries (CZI) 2017 manufacturing sector survey report, companies with older machinery and equipment did not record any growth in the period under review, an indication that industry without machinery is dead.

Output growth was only recorded by companies whose machinery was less than 10 years old.

CZI Matabeleland chapter president, Joseph Gunda told NewsDay that without retooling, it was almost impossible to power industry.

"Funding support for re-tooling at low interest rates should be provided as a matter of urgency to local companies that need to upgrade or bring in new equipment or technology. Funding should be made available for re-tooling in earnest, as most manufacturing firms are using antiquated equipment," he said.

"While the new dispensation is focusing on opening the economy to foreign direct investment, the manufacturing industry should, on the other hand, be focusing on introducing modern processes, technologies and equipment that will help us to manufacture high quality products at low cost and enable our products to be competitive at regional and international level. We need to be in state of preparedness for competition."

Funding in Zimbabwe is short-term with lending rates averaging 12% per annum.

When the country adopted a multi-currency system in 2009, lending rates were as high as 35%, but have now gone down to around 12% on average.

But companies say this is still too high.

Recently, Reserve Bank of Zimbabwe deputy governor, Kupukile Mlambo revealed that they were working with banks to find ways of increasing long term cheaper financing to cushion companies, ahead of the envisaged massive investment under the new economic order.

Following the coming in of a new political dispensation, the government has embarked on a programme to lure investors from across the globe through re-engagement with the international community after over a decade of isolation.

But for that to effectively happen, long term funding for local companies is needed, as the machinery is making their products uncompetitive, both regionally and internationally.

Economic analyst, Reginald Shoko said companies were using machinery that belonged in a museum.

"There is a cocktail of challenges facing manufacturers in the economy, the shortage of foreign exchange being the most prominent one due to its direct effect to matters like retooling. Most of the machinery is very old and belongs to a museum," he said.

"Foreign exchange is needed for the importation of raw materials. Due to the old machinery the products will not be competitive, hence, the expensive retail prices on the market, which attracts the consumer to foreign products, which are cheaper and of better quality."

There have been reports since last year that the government had set aside funding for the recapitalisation of companies whose products were placed on import restrictions under Statutory Instrument 64 of 2016, but nothing concrete has been noticed.

CZI said Zimbabwe's manufacturing sector requires about $8 billion for working capital and equipment upgrades to arrest a downward spiral in capacity utilisation and collapse of firms due to viability challenges.

Manufacturing sector's capacity utilisation dropped 2,3% from 47,4% in 2016 to 45,1% in 2017 due to a number of factors, chief among them use of obsolete machinery.

Shoko said another issue affecting local industry was high labour costs.

"High labour costs in Zimbabwe are also a big challenge for the manufacturers. We have the highest minimum wages in the region mainly due to the use of the American dollar in circulation. The issue of electricity tariffs needs to be looked into with a view of boosting the manufacturing sector," he said.

- newsday

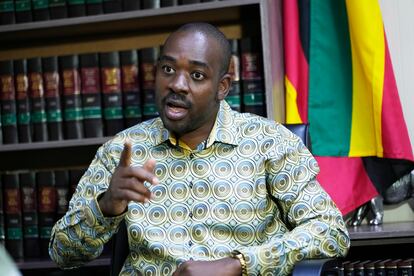

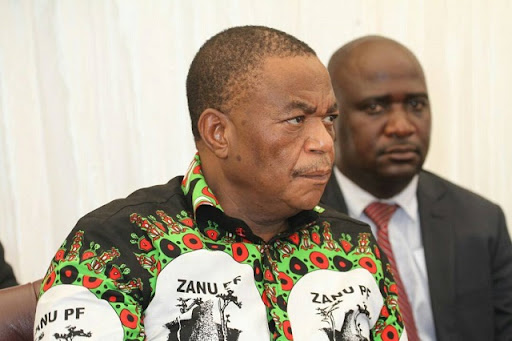

Chamisa rejects coup-like actions

Chamisa rejects coup-like actions  ZEP extension faces pushback

ZEP extension faces pushback  'Some very strange things are happening in China!'

'Some very strange things are happening in China!'  Zimbabwe's dollar stock exchange surges 45%

Zimbabwe's dollar stock exchange surges 45%  Gold edges up as traders await guidance

Gold edges up as traders await guidance  Zimbabwe named World's best country to visit in 2025 by Forbes

Zimbabwe named World's best country to visit in 2025 by Forbes  Young Investment Professional (YIP) Graduate Programme 2019

Young Investment Professional (YIP) Graduate Programme 2019

Young Investment Professional (YIP) Graduate Programme 2019

Young Investment Professional (YIP) Graduate Programme 2019

Editor's Pick